Enovate® 245fa Blowing Agent Improves Cryogenic Pipe Insulation Performance

Enovate® 245fa Blowing Agent Improves Cryogenic Pipe Insulation Performance - A case study published by HONEYWELL

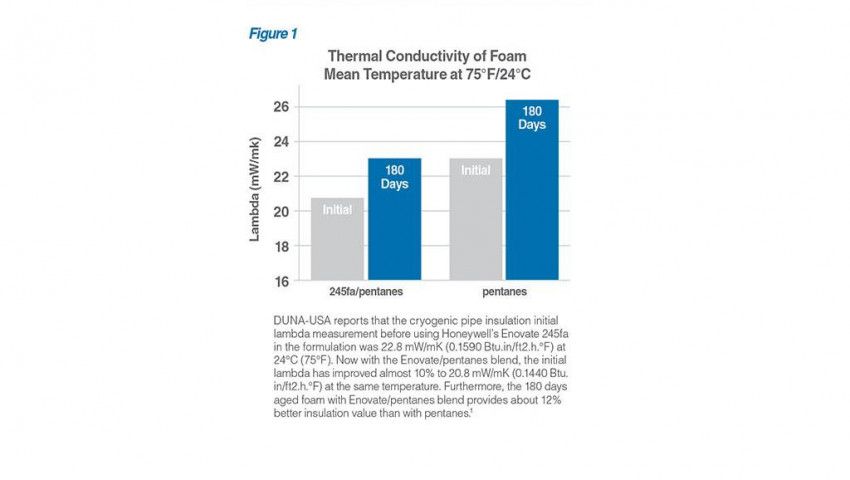

DUNA-USA reports 12% better thermal conductivity by adopting Enovate for its rigid foam LNG pipe insulation.

“Since converting from pentane foam blowing agents to an Enovate/ pentanes blend in one of our cryogenic pipe insulation products, we’ve experienced increased processability, greater mold flowability, better flame spread index and most significantly, improved insulation value.” - Franco Sala, Engineering Manager, DUNA-USA Inc., Baytown, Texas, USA

DUNA-USA Inc. is a leading manufacturer of polyurethane (PU) and polyisocyanurate (PIR) foams for a variety of applications, including cryogenic and thermal insulation. Serving the growing market for liquefied natural gas (LNG), it offers a line of rigid PU/PIR foam cryogenic pipe insulation products in a variety of shapes and sizes.

BACKGROUND

Natural gas is a major international commodity that must be produced, stored and shipped safely and cost-efficiently. Typically, pipelines are used to transport natural gas over land. However, to transport natural gas overseas, it must be converted into LNG through the liquefaction process. During LNG production, cryogenic insulated pipes are used in the process to liquefy the natural gas reducing it to 1/600th of its volume. The natural gas is condensed into a liquid by cooling it to approximately -165°C and separating it from other secondary gases at the same time to get pure product. Once the gas is liquefied, it must be kept at cryogenic temperatures of -163°C to prevent it from boiling and evaporating. If the LNG reaches its boiling point of -161°C, the gas will boil off. To help prevent boil-off, high quality insulation plays a vital role during LNG production, transportation and storage.

RIGID FOAM — A POPULAR CHOICE FOR CRYOGENIC PIPE INSULATION

Among the most energy efficient cryogenic insulations are those made with rigid closed-cell PU or PIR foam. At DUNA-USA, small pipes are typically insulated with cylindrical half sections of PU or PIR insulation fitted with factory-applied jackets (finishes). Large pipes may be insulated with curved segments with fittings and valves also being insulated. The insulation is secured using a variety of methods. For small pipes, insulation with certain types of jacketing may be secured by cementing the overlapping jacket. On large pipes, additional wiring or banding around the circumference may be required.

Some typical DUNA requirements for LNG pipe insulation include:

• Low thermal conductivity (lambda) — The low thermal conductivity of rigid PU foam allows efficient retention of heat flow, improving insulating performance.

• Strength — Insulation should be load-bearing, impact resistant, and space saving.

• Lightweight — PU foam is very lightweight facilitating ease of transportation, handling and installation.

• Low water absorption/permeability — Water reduces insulating efficiency, increases weight and can cause corrosion, ice formation and deterioration. Closed-cell PU is inherently water-resistant.

• High dimensional stability — The size fluctuation when a material is heated or cooled must be considered when designing an insulation system. Rigid PU foams have high dimensional stability, thereby reducing size changes.

• Performs under harsh conditions — Rigid PU foam can be used in applications which face extreme temperatures (from -195°C to +149°C).2 It resists a wide range of chemicals, solvents and oils and is compatible with many auxiliary materials.

NOT ALL BLOWING AGENTS ARE CREATED EQUAL

Many pipe insulation producers use HCFC-141b or pentanes as the foam blowing agent in their PU or PIR foam system formulations. Although DUNA has been using pentanes for U.S.-based production, it has been successfully using HFC-245fa blowing agent in Europe for over 10 years. In January 2015, DUNA-USA converted from pentanes to an Enovate 245fa/pentanes blend for its CORAFOAM®PB 40 M1-HC rigid foam pipe insulation.“Since this transition, we have seen a number of performance advantages with the most significant being a 10-12% improvement in thermal conductivity or lambda,” said Sala. Additional benefits include better production control and a smoother, tighter foam structure.

A FOCUS ON THE ENVIRONMENT

With heightened awareness about climate change, governments are now discussing a movement away from HFCs to alternative blowing agents, such as hydro-fluoro-olefins (HFOs). HFOs are nonflammable, non-ozone depleting and offer an ultra-low global warming potential (GWP) of one, 99.9% lower than HFCs and equal to or lower than CO2. HFOs also improve foam performance and can be a near drop-in replacement for many blowing agents being phased out under global environmental treaties or regulatory action. With a strong commitment to safety and sustainability, DUNA Group is planning to evaluate Honeywell’s HFO-based Solstice® Liquid Blowing Agent (LBA) as an eventual replacement for HFC-245fa.

Solstice LBA is being adopted globally by a growing number of closed-cell PU foam manufacturers and systems houses for a wide range of applications including spray foam for commercial and residential construction, rigid panels, appliances, piping, storage tanks and others. Solstice LBA is commercially produced at Honeywell’s worldscale facility in Louisiana. Sala added, “Not only does the Honeywell team provide us with excellent technical and sales support, they help us stay ahead of the evolving regulatory environment with blowing agent technology that not only improves our environmental performance, but also delivers better insulation performance.”

Foam Blowing Agents: A Huge Impact On Insulation Performance

During the foam reaction, the blowing agent, in the form of tiny gas bubbles, is trapped inside millions of cells of the polymer matrix. Not only does the blowing agent help expand the foam typically to 30 times or more of its original volume, it has a huge impact on the foam’s performance, especially its insulating value. The polyurethane matrix is in charge of holding all the cells together; the higher the amount of polymer that holds together the structure, the higher the density. In fact, in 1 cubic meter of foam, only 4% of the total volume is occupied by the polymer, while the remaining 96% is filled by the blowing agent (applies to a typical 40-45 Kg/m3 foam).2 The type of blowing agent strongly influences many properties of the finished LNG insulating foam, such as its thermal conductivity (lambda), mechanical strength, weight, dimensional stability, flammability, as well as its environmental profile.