CORINTHO® is an entirely new style of polyurethane modeling and tooling boards designed by our R&D team to be the DUNA Group’s flagship product for all sectors requiring a high degree of precision, detail and machinability (both manual and CNC machines).

APPLICATIONS:

· Carbon prepreg layup molds

· Master models

· Vacuum forming

· CAD Design verification, prototyping

· Composite layup tooling

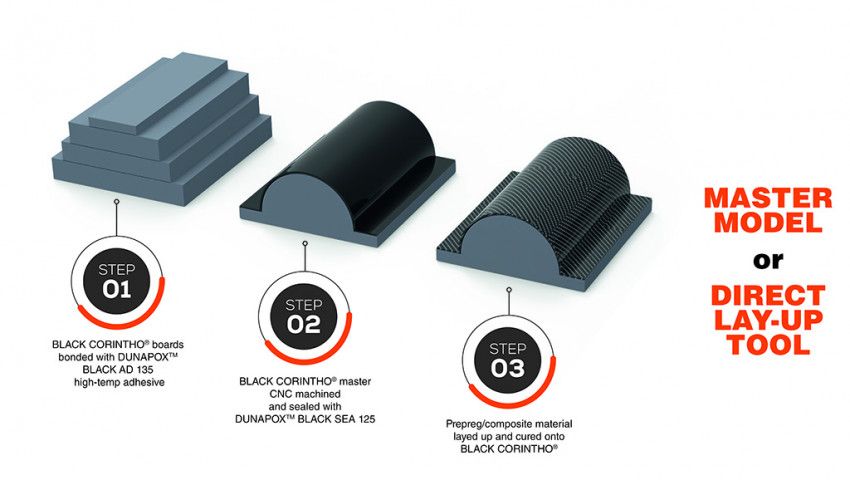

BLACK CORINTHO®

BLACK CORINTHO® is a low CTE, high-temp, highly stable polyurethane tooling board designed for a wide variety of tooling applications.

Its high thermal conductivity allows quicker autoclave and oven processing.

Designed to expand and contract under temperature, the BLACK CORINTHO® is ideal for use with high or low-temperature curing prepregs where a high degree of stability or dimensional tolerance is desired.

FEATURES

· 400°F service temperature

· High thermal conductivity = faster autoclave processing

· Ultra-low CTE, excellent dimensional stability

· High quality surface finishing

· Easy to machine, non-abrasive

APPLICATIONS

· Carbon pre-preg layup molds

· Master model

· Vacuum forming

· Prototyping modelling

BLUE CORINTHO® HT

BLUE CORINTHO® HT is a rigid polyurethane tooling board with an exceptionally high glass transition temperature of +509°F.

BLUE CORINTHO® HT is particularly suitable for master models and layup molds. It is also successfully used to make thermal breaks or supports in cryogenics.

FEATURES

· 400°F service temperature

· High surface finishing and excellent internal consistency

· Ease of machining

APPLICATIONS

· Master model

· Vacuum forming

· Prototyping modelling

· Thermal breaks

· Cryogenic supports

BLUE CORINTHO®

Polyurethane board developed for modeling applications, tooling, rapid prototyping and vacuum forming at high-medium temperatures (up to 250°F). Along with the other products in the CORINTHO® line, it offers dimensional stability and chemical resistance.

ACCESSORY MATERIALS:

Our tooling solutions include accessory materials, designed to withstand high temperatures in autoclave and oven up to 400°F without cracking or degradation and to expand and contract with tool under temperature. Available in blue or black coloring.

- Bonding: DUNAPOX™AD 135: Thixotropic, epoxy adhesive.

- Sealing: DUNAPOX™ SEA 125: Epoxy sealer. Can be sprayed, brushed or rolled. Once hardened, DUNAPOX™ SEA can be flatted “sanded” and polished to a high gloss. Cures to a tough, Shore D 85 protective surface.

Tooling guidelines available on request.

Please also see our CORAFOAM® High density line of polyurethane tooling boards for pattern making, vacuum forming, check fixtures, and more.

| BLUE CORINTHO® 700 | BLUE CORINTHO® HT 700 | BLACK CORINTHO® 800 | BLACK CORINTHO® 1100 | |||

|---|---|---|---|---|---|---|

| Nominal density | EN ISO 845/EN 1602/ASTM D1622 | lb/ft³ | 43.6 | 43.6 | 49.9 | 68.7 |

| Hardness | ASTM D2240/EN ISO 868 | Shore D | 57 | 63 | 50 | 60 |

| Compressive strength - Parallel (23°C) | ASTM D1621/EN 826 | psi | 3190 | 4061 | 2176 | 5801 |

| Compressive Modulus - Parallel (23°C) | ASTM D1621/EN 826 | psi | 40610 | 65267 | 31908 | 78900 |

| Flexural strength - Parallel, Met.I (23°C) | ASTM C203/EN 12089 | psi | 2465 | 3336 | 1015 | 2465 |

| Flexural modulus - Parallel (23°C) | ASTM C203/EN 12089 | psi | 91374 | 108778 | 95725 | 237862 |

| Max.flexural strain (23°C) - Met.I | ASTM C203/EN 12089 | length/length | 0.032 | 0.035 | 0.012 | 0.014 |

| Operating temperature | °F | -328/+248 | -328/+400 | +32/+400 | +32/+400 | |

| Thermal conductivity - Initial (24°C) | ASTM C518/EN 12667 | BTU·in/hr·ft²·°F | 0.66 | 0.75 | 1.83 | 2.63 |

| Glass transition temperature (Tg) | ASTM E1356/EN ISO 113572 | °F | 293 | 509 | 464 | 464 |

| Coefficient of linear thermal expansion CTE (+90/160 °F) | ASTM E228/EN13471 | 1/°F·10E-6 | 19 | 14 | 3 | 6 |

| Coefficient of linear thermal expansion CTE (+90/250 °F) | ASTM E228/EN13471 | 1/°F·10E-6 | 61 | 15 | 5 | 7 |

| Coefficient of linear thermal expansion CTE (+90/360 °F) | ASTM E228/EN13471 | 1/°F·10E-6 | 132 | 45 | 12 | 11 |

| Dimensional stability (180°C) - Length; Width; Thickness | ASTM D2126/EN 1604 | % | n.d. | -1,58; -1,53; -0,83 | -0,20; -0,20; -0,25 | -0,20; -0,20; -0,25 |

| Fire reaction | FAR 25-853A | n.d. | 12"/60" Passed | 12"/60" Passed | 12"/60" Passed |